|

Gear wheel calculator

|   |

Gear wheel module

Field of application

The gear wheel module allows to overlay the live image with

the outlines of a freely definable gear wheel.

Currently only the involute tooth shape can be displayed.

The next stage of development will include the tooth shape

cycloid e.g. for gear wheels of clocks.

So, two different application areas can be defined:

1.

By adapting the gear wheel parameters, the outline of the

gear wheelcan be approximated. As soon as the outline

matches the live image,the parameters can be read out.

2.

The nominal parameters are adjusted in the program window,

then the outline overlays the live image. That way irregularities

from the nominal condition can be discovered quickly.

A faded in gear wheel can be easily adjustet by the means of

the hair cross single rotatable. In the process the arrow keys

and the keys " + "and " - " work as described at the keyboard

Handling of the module

At the end of the toolbar stands this button ![]() representing a

representing a

stylised gear wheel. By pushing it, a new window is opened

where the gear wheel can be defined.

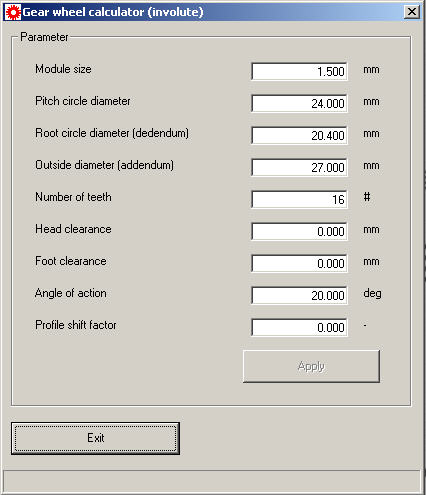

The following image shows the parameter window of the gear

wheel module.

The basic dimensions of a gear wheel are:

- Module size

- Number of teeth

From this, a standardized gear wheel can be completely

calculated.The size of the module of millered gear wheels is

due to the applied tool,thus the module size of the mill.

The number of teeth is obviously offered by counting.

Reference note: With a large number of teeth it is recomended

to use the measurement program function "count", since each already

counted tooth is marked.

Having entered a new module size and pushed the button "Apply",

the dimensions "Pitch circle diameter", "Root circle diameter" and

"Outside diameter" will be newly calculated.

The method is similar, when the number of teeth is modified.

With unknown gear wheels, it may happen, that the size of the

module deviates from the standard. In that case the outside or root

circle diameter can be determined using the functions "diameter" or

"(multi point-) circle". Hence results a first clue for the module.

Thus the module is newly calculated when entering the outside-,

pitch- or root circle diameter.

The dimensions "Module size","Outside diameter", "Pitch circle

diameter","Root circle diameter" and "Number of teeth" are associated

with each other, so they can not be determined undependently of

each other. By pushing "Apply" the at a time dependend parameters

are newly calculated.

The parameters "Head clearance" and "Foot clearance" affect directly

on outside- and root circle diameter. There consists no effect on the

other parameters. The meaning ot these parameters immediatly

results from their names: with standarized gear wheels running, the

tooth tip would touch the tooth root. To give this running more

clearance, the tooth can be shortened at the tip or milled out deeper.

Accordingly the head and foot clearance rise.

The parameters "Angle of action" and "Profile shift factor" change the

tooth shape.The profile shift factor is the easiest to understand. It means

that the module milling cutter of the machine is feeded more or less.

Correspondingly the teeth are milled more or less deep into the gear

wheel.

For the pressure angle imagine the mode of operation of a gear pair.

Connect both centres of the gear wheels with an imaginary line. At the

first contact the teeth touch each other at a certain point. While running

this contact point slips on a line until both teeth loose the contact again.

This line is called "Line of action". The angle which this line takes over

towards the vertical reference line is named "Angle of action". Via the

angle of action the transverse contact ratio, and thus wear and running

smoothness of the gear, are determined.

The parameters "Angle of action" and "Profile shift factor" do not have an

affect on the other parameters, and are independent from them. They only

change the shape of the teeth.

Example for the adaption of the parameters to a present gear wheel

The calibration of the lens is a basic requirement.With the function "Count"

the number of teeth is determined. This number can be entered directly

into the parameter window. After each activity the "Apply" button must be

pushed.

With the function "Diameter" or "Diameter LSC" the root circle diameter

and th eoutside diameter can be determined. Since these dimensions are

dependent from each other, it makes no sense to enter them one after the

other into the parameter window. In fact, an indication for the module size

results from these measurements

The profile shift factor initially should remain at 0.

Typically the pressure angle is 20°, at automobile technology often 17,5°

and with special gear wheels "high gearing" it can be reduced until 5°.

Enlarged angles of action lead to narrow head and an extended foot.

Smaller angles of action lead to an extended head.

After the size of the module has been approximately determined by the

outside diameter and/or the root circle diameter, the size of the module

will now be adjusted directly, so that the shape of the teeth is optimal

approximated .

If, by this adaption the outside- and/or the root circle diameter are

aligned worse, alter the head- respectively the foot clearance.

If this leads to the teeth beeing all in all to narrow or to expanded,

the profile shift factor must be modified.

If the head of teeth is to expanded and the foot is to narrow, the angle

of action must be changed.