|

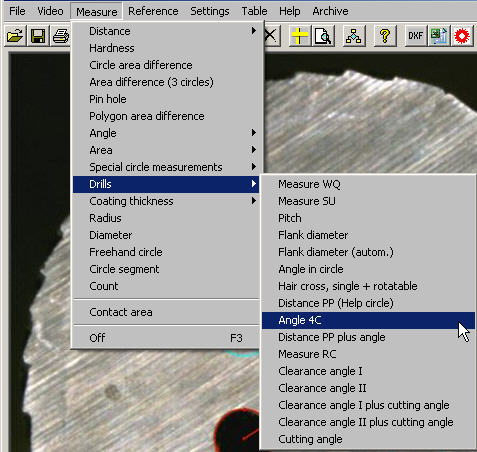

Angle 4C

|   |

Angle 4C - standard variant

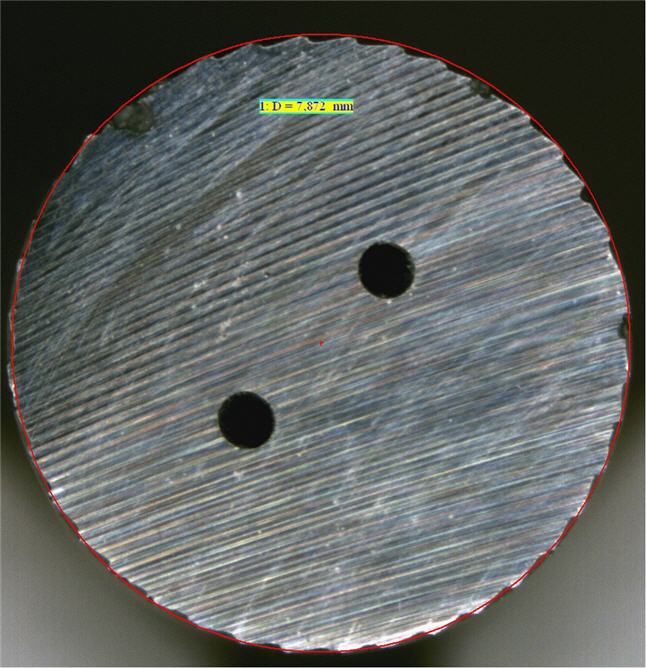

This function is used to determine the lead of twisted coolant bores of raw

bars for the production of inner coolant drills with two or more round coolant

bores which have an equal diameter.

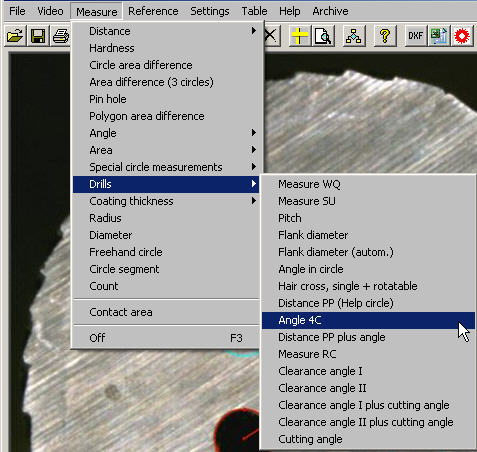

After positioning and focussing the raw bar in the prism, activate the function

"Angle 4C ".

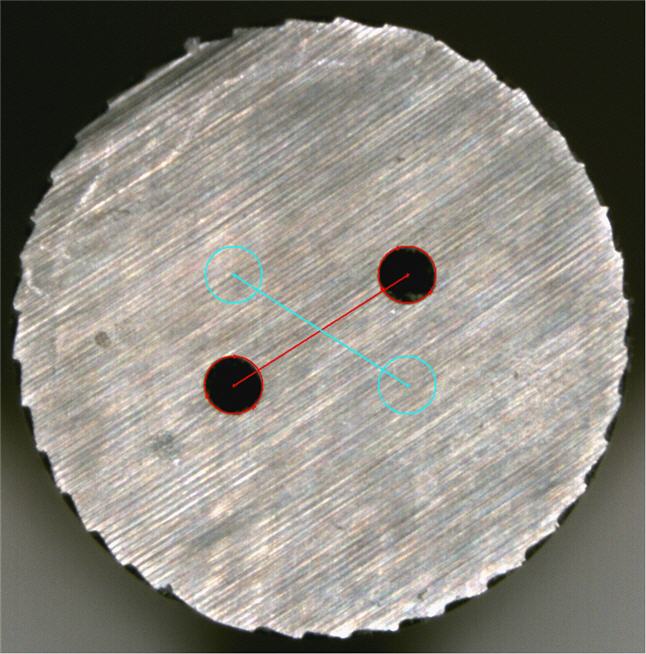

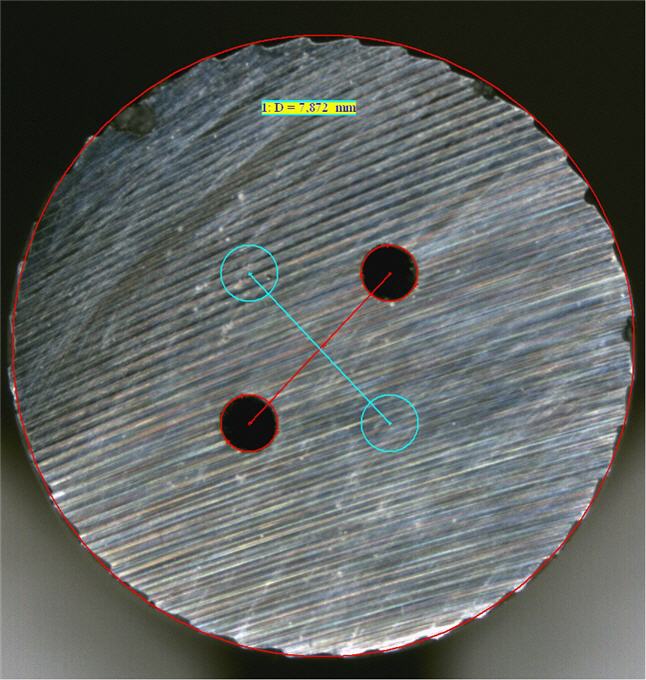

Start to construct a circle with three points either left or right. Then click

on the second bore with tree points. Automatically an auxiliary construction appears.

Now rotate the prism with the bar 180° about the horizontal axis.

ATTENTION: The measurement of the second side of the bar has to be

startedfrom the same bore as on the first front face.

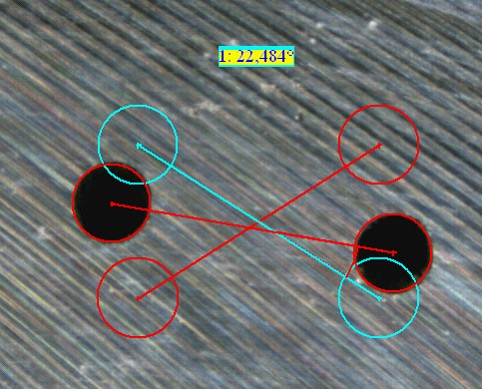

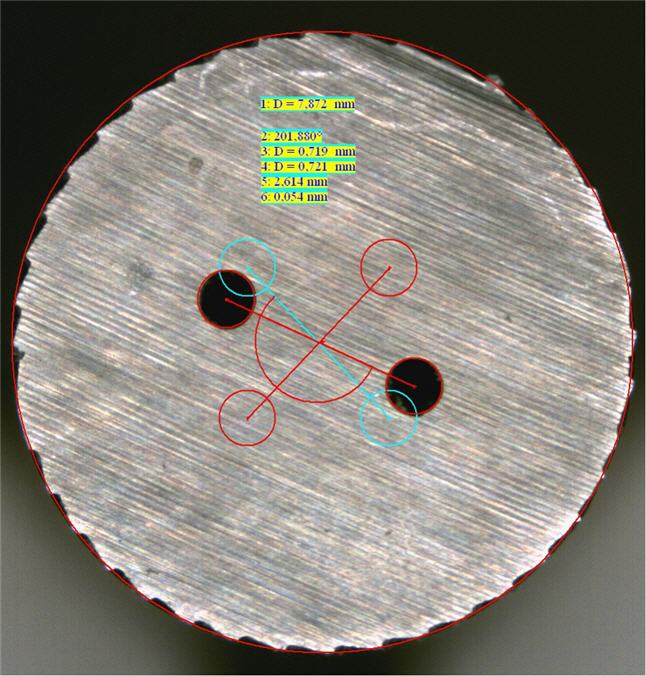

Set again three points per bore and finish the measurement by pushing the

right mouse button. The angular dimension is indicated now.

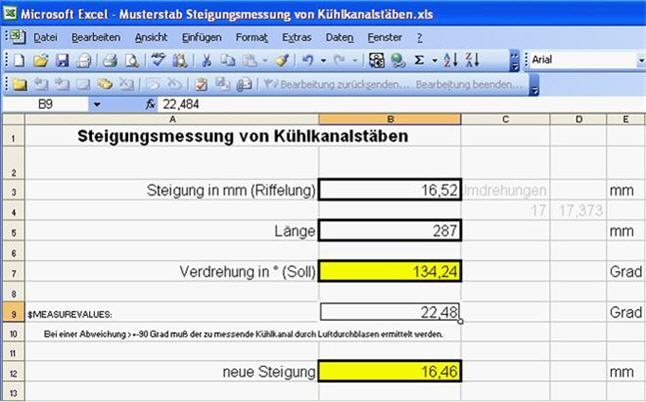

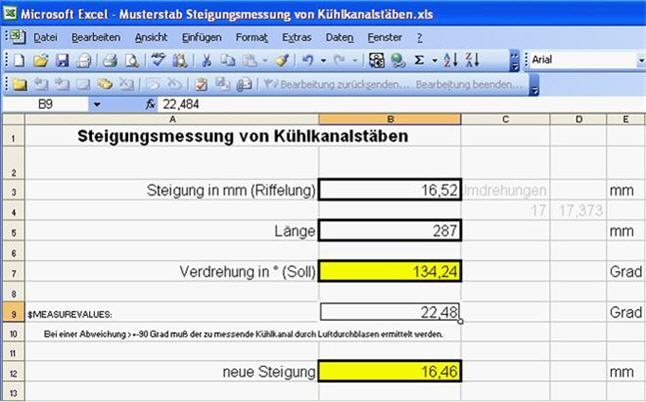

To calculate the "Is-thread" enter the determined angle into the table element

B9 of the excel protocol and the "Is-value" will be computed automatically.

It is a pre-condition for a correct determination of the value, that the

manufacturers`instructions about the "nominal thread" and the correct length

have been entered into the table elements B3 and B5 before.

Extended Measure function Angle 4C

This function is used to determine the lead of twisted coolant bores of raw

bars for the production of inner coolant drills with two or more round coolant

bores which have an equal diameter, as well as the following measurements:

Diameter of the raw bar

Distance between the centres of the coolant bores

Centre-offset of the coolant bores

Diameter of coolant bore 1 and 2

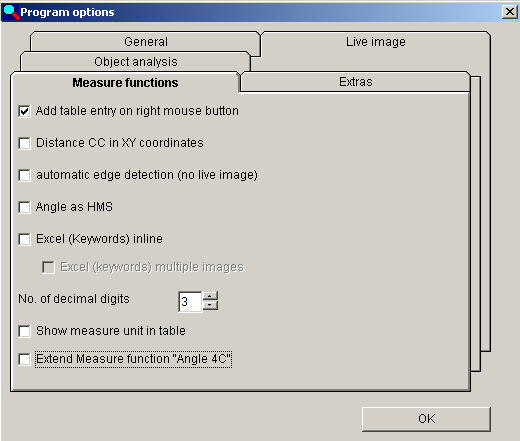

To achieve these additional values activate "Extend Measure function

Angle 4C" at "Program options" → "Measure functions"

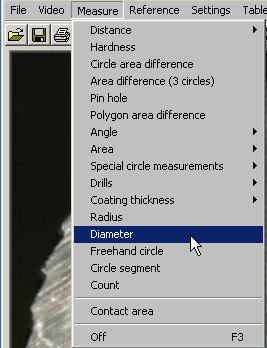

After positioning and focussing the raw bar in the prism, activate the function

"Diameter ".

Set three points to determine the outer diameter of the raw bar and push the

right mouse button to enter the result.

Now activate "Angle 4C”.

Start to construct a circle with three points either left or right. Then click

on the second bore with tree points. Automatically an auxiliary construction

appears.

Now rotate the prism with the bar 180° about the horizontal axis.

ATTENTION: The measurement of the second side of the bar has to be

startedfrom the same bore as on the first front face.

Set again three points per bore and finish the measurement by pushing the

right mouse button. All measured values are indicated now.

To calculate the "Is-thread" enter the determined angle into the table element

B9 of the excel protocol and the "Is-value" will be computed automatically.

It is a pre-condition for a correct determination of the value, that the

manufacturers`instructions about the "nominal thread" and the correct length

have been entered into the table elements B3 and B5 before.

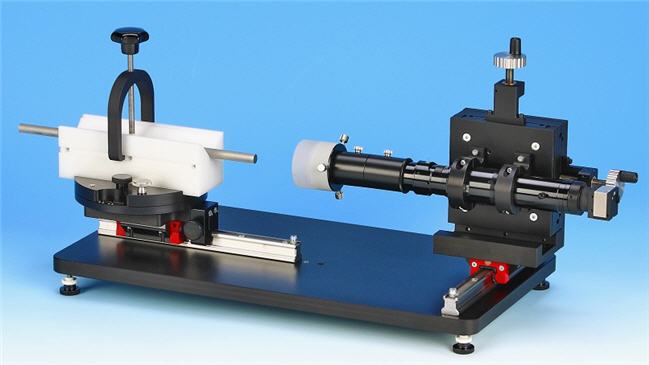

For serial measurements use the model CT-9000, which was designed for this

purpose, because this device includes an about 180° rotatable precision

table with an insertion prism.